Universal large chain making machine for 3.0mm cable chain-Set up a new chain factory in Portugal -February 2025

In February 2025, ESTAR TECH's technicians assisted the customer in setting up a new cable chain production line in Portugal. As it was more convenient for the customer to purchase wire locally, we installed annealing furnaces, 12 dies wire drawing machines, plasma welding chain making machines, large chain making machines,chain hammering machine and polishing machine at the place.

However, 316L stainless steel has different hardness and tensile strength in different countries, making the production of 3.0mm stainless steel cable chain is really a challenging task. We tested different specifications of stainless steel and different types of oil to find the most perfect match to meet production standards,after the drawing machine and drilling machine we got the solution .

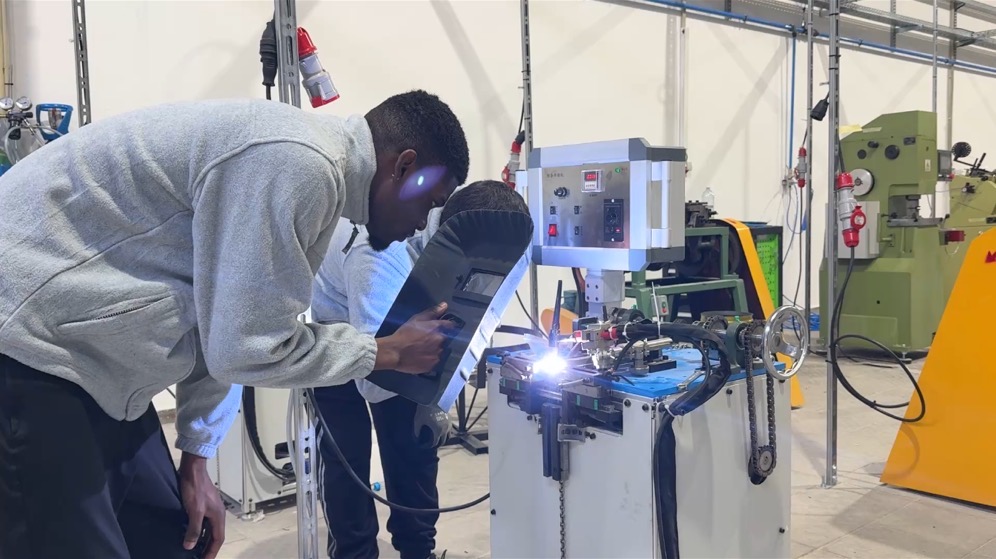

At the same time, the welding part is also crucial. Because the chain wire diameter is too large, the conventional welding system cannot directly weld and penetrate the completed 3mm cable chain.

We use an automated large-scale plasma welding machine. User only need to put the completed chain into the feed trough, adjust the frequency, speed and firepower, and then complete the automated welding.

Finally, ESTAR TECH engineers conducted two weeks of testing and debugging at the customer's site, and completed this exciting project with rich mechanical experience.

More details and Recording Video please kindly check to our official Youtube link:

|

https://www.youtube.com/watch?v=OgSzYA97A1A |

If you have a new chain machine production line need to set up or build in , please feel free to email us to discuss your requiemens and details.

manager@estar-tech.cn

Our services include but are not limited to:

1. **Equipment installation and commissioning**: Our professional team will ensure that your equipment is successfully installed and efficiently operated abroad.

2. **Regular maintenance and care**: Regular maintenance and care services ensure long-term stable operation of equipment and extend service life.

3. **Emergency troubleshooting**: In the face of sudden failures, we provide fast-response repair services to minimize equipment downtime.

4. **Technical and operational training**: Provide professional training for local operators to improve their operating skills and maintenance capabilities.

5. **Spare parts supply and logistics support**: We provide original spare parts and optimize the logistics chain to ensure timely delivery of spare parts.

Choose us, you will get: **Professional technical team**: Experienced, skilled, and able to solve various complex problems.

**Global service network**: Covering a wide range of service networks to ensure that there are no blind spots in service.

**Quick response mechanism**: 24/7 standby, quickly respond to your service needs.

**Customized solutions**: Provide tailored service solutions based on your specific needs.