Use the variable hammer machine to make regular cable chain into lip chain-Riyadh Saudi Arabia-April 2025

As we known that there are many different types of necklaces in the world, all of which can be transformed using various molds.

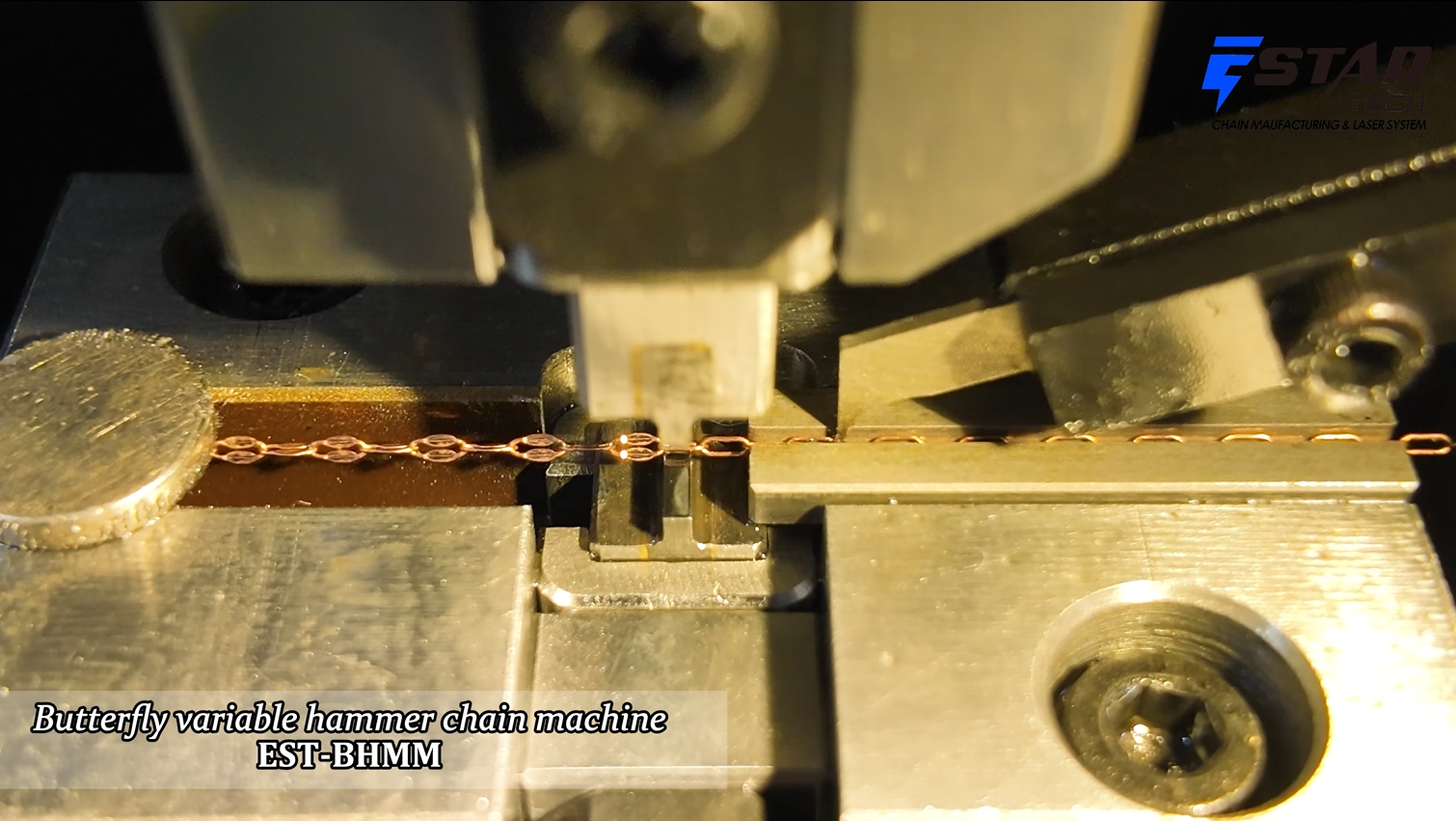

In this case, we will use a variable hammering machine to produce a cable chain variation—a lip chain

-

Design Specifications:

- A lip chain is characterized by having a flat, lip-like appearance. It is a variation of the cable chain where the links are hammered to flatten them, giving a wider and more reflective surface.

- The chain will consist of interconnected oval or round links that are then hammered to flatten and shape them into the lip design. -

Machine Setup:

- The variable hammering machine must be set to a specific force and pattern to achieve the desired flatness and shape without breaking the links.

- We need to adjust the machine for the thickness of the wire and the desired final dimensions.

|

Model :EST-BHMM Wire diameter:0.19-0.9mm Weight:140KGS Dimension:44*73*102cm Power supply:Single phase 220V 50-60HZ |

- Hammering: Place each link in the hammering machine and flatten it. The machine should be set to apply pressure in a way that flattens the link but maintains the oval shape and creates the "lip" effect (which might involve a specific curvature or edge).

- Material Selection: Typically, chains are made of metals like gold, silver, or platinum. Since the customer is from Saudi Arabia, gold (especially 18K or 21K) might be preferred due to cultural affinity for gold jewelry.

|

before |

after hammering |

|

before |

after hammering |

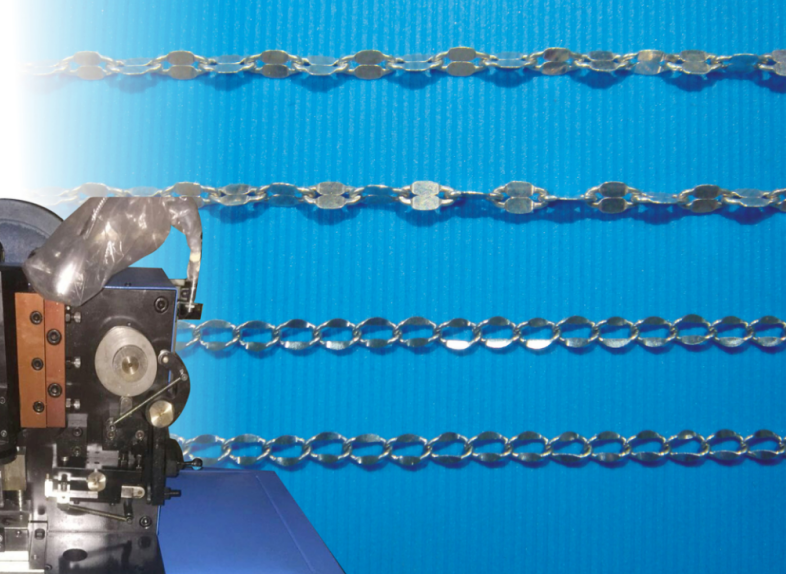

Also the variable hammering machine can not make only one styles of chain,see the following as reference :

(common each necklace length =50-60cm)

Machine working video please check our official Youtube link:

|

https://www.youtube.com/watch?v=z-jZ394x05M |

If you have a new chain machine production line need to set up or build in , please feel free to email us to discuss your requiemens and details.

manager@estar-tech.cn

Our services include but are not limited to:

1. **Equipment installation and commissioning**: Our professional team will ensure that your equipment is successfully installed and efficiently operated abroad.

2. **Regular maintenance and care**: Regular maintenance and care services ensure long-term stable operation of equipment and extend service life.

3. **Emergency troubleshooting**: In the face of sudden failures, we provide fast-response repair services to minimize equipment downtime.

4. **Technical and operational training**: Provide professional training for local operators to improve their operating skills and maintenance capabilities.

5. **Spare parts supply and logistics support**: We provide original spare parts and optimize the logistics chain to ensure timely delivery of spare parts.

Choose us, you will get: **Professional technical team**: Experienced, skilled, and able to solve various complex problems.

**Global service network**: Covering a wide range of service networks to ensure that there are no blind spots in service.

**Quick response mechanism**: 24/7 standby, quickly respond to your service needs.

**Customized solutions**: Provide tailored service solutions based on your specific needs.