Cartier necklace chain making process-Saudi-August-2025

We all know that chain weaving (making) machines are specialized automated equipment for the efficient production of metal chains(such as gold,silver,brass,steel). Its core feature is the use of precision molds and stamping mechanisms to continuously bend, weave, or link metal wires into shape, achieving high-speed, mass production and ensuring uniform chain links. It can produce a variety of complex chain types (such as box chains, cable chains, etc.) with far greater efficiency than manual work and high precision.

However, basic molds cannot produce more complex chain styles. For example, Cartier chain.

In this article we will introduce in detail how to use machinery to mass produce high-precision and high-quality Cartier chains.

Initially you need to prepare enough cable chains,if you are interested in manufacturing cable chains you can check out our model EST-F450.

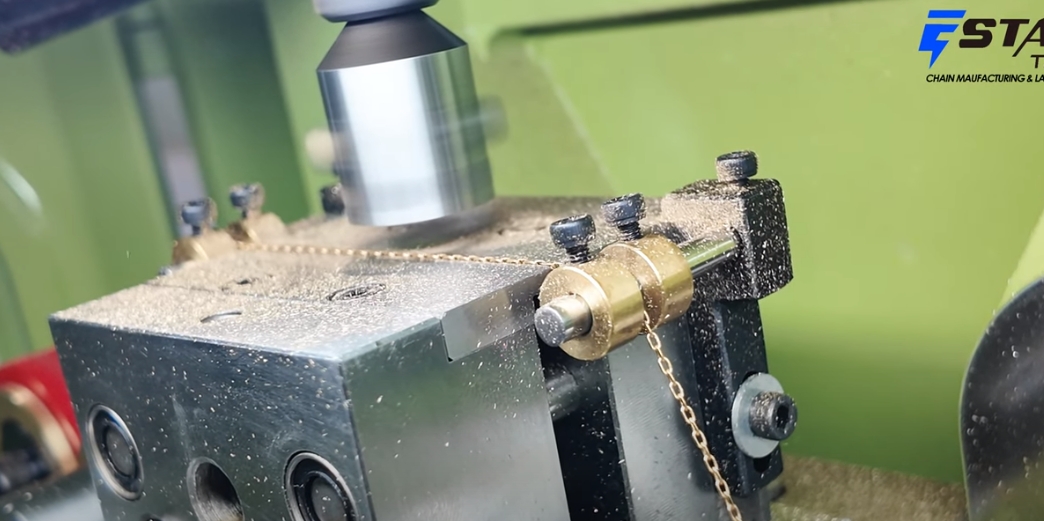

Put the cable chain into the bobbin of the faceting diamond cutting machine. Usually, there are 2 cutter heads, 4 cutter heads, and 8 cutter heads available inside the machine. Our model uses 2 cutter heads as a demonstration.

First step ,cut the two sides of the cable chain. After that, rewind the cable chain that has been cut on two sides into the bobbin and continue cutting the other two sides.

This lathe can quickly and accurately cut smooth cross-sections, enabling efficient mass production.

Its sealed structure and internal recovery device can also recycle precious metal chips scattered during the cutting process, minimizing waste and promoting recycling.

| Before cutting | After cutting |

|

|

If you want to check out more working video of machine , please go head to our Youtube channel as below :

|

https://www.youtube.com/watch?v=HyjJ7jZVX9Q |

Any question you can feel free to contact us :

Email:manager@estar-tech.cn

Whatsapp:+86 13027832588